Welcome to Cyborg Industries Pvt. Ltd.

PLC, HMI, SCADA & Instrumentation

Reliable Automation Panels for Your Coating and Plating Plants

Surface Treatment Automation Panel Solutions

We support only the control system side of your Electroless Plating, ED, and Powder Coating Plants.

Our team provides reliable automation support using:

Custom-built Control Panels

Advanced PLC + HMI Programming

SCADA Visualization Systems

Process Instrumentation & Integration

Scope of Our Expertise

01

Electrical Control Panel Design & Manufacturing

02

PLC & HMI Logic Development

03

SCADA Development & Remote Monitoring

04

Integration of Field Sensors & Instruments

Applications & Solutions

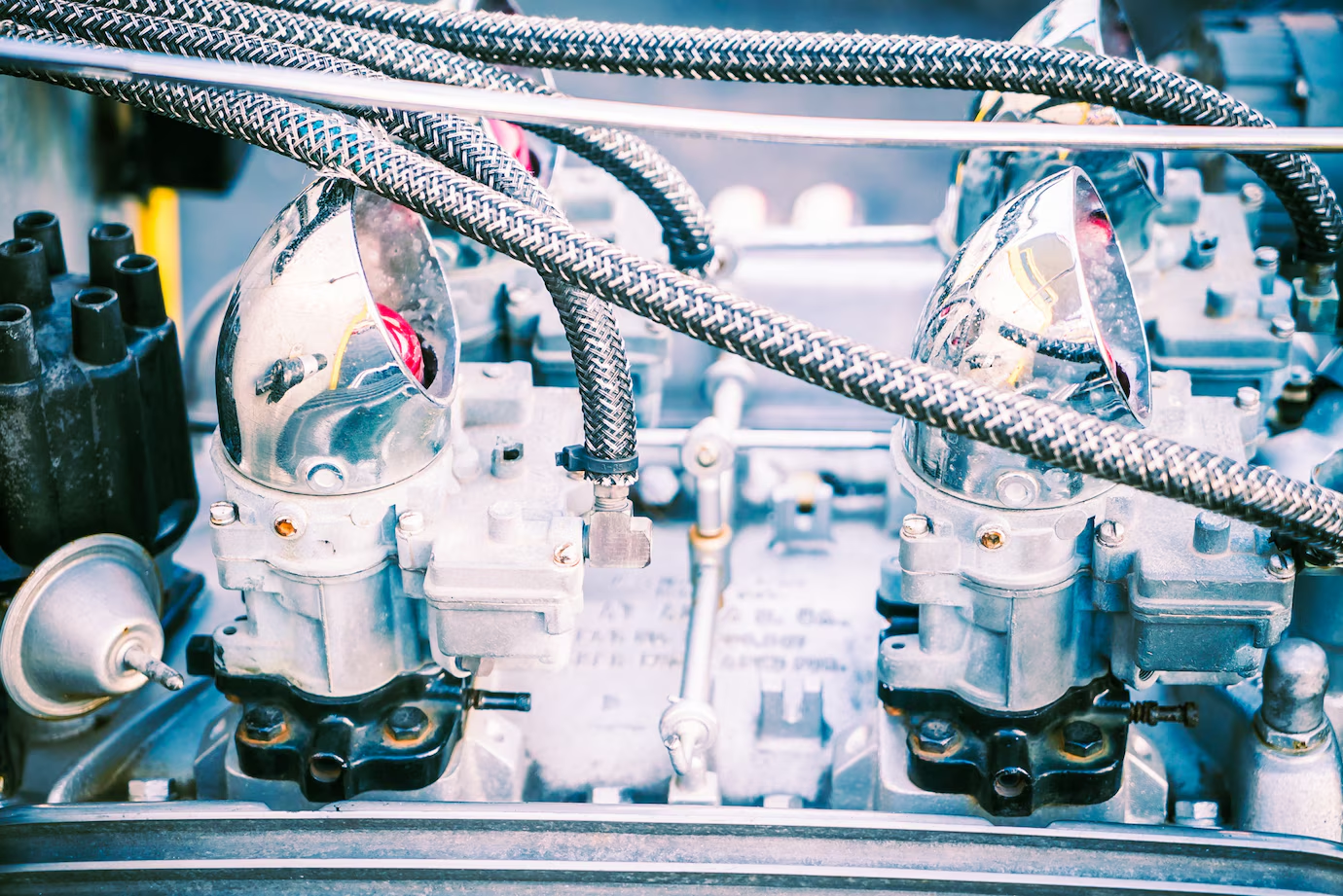

Automation Panels for Surface Treatment Plants

Surface treatment plants involve complex sequences of cleaning, plating, anodizing, phosphating, and painting processes that demand precise control over timing, temperature, chemical dosing, and material handling.

Application: Chrome, Nickel, Zinc, Tin, and Copper plating

Features: Auto-transfer system control, tank heating, rectifier control, chemical dosing, agitation, and filtration control.

Features: Auto-transfer system control, tank heating, rectifier control, chemical dosing, agitation, and filtration control.

Application: Aluminum component anodization

Features: Precise current and voltage control, rectifier timing, temperature feedback loop, automated hoist system control.

Features: Precise current and voltage control, rectifier timing, temperature feedback loop, automated hoist system control.

Application: Surface cleaning and oxide removal for steel, aluminum, copper

Features: Step sequence control, timer-based agitation, fume extraction, and heater interlocks.

Features: Step sequence control, timer-based agitation, fume extraction, and heater interlocks.

Application: Surface preparation before powder coating or painting

Features: Sequential timer-based control of spray zones, temperature control for tanks, pump/VFD automation, and safety cutoff logic.

Features: Sequential timer-based control of spray zones, temperature control for tanks, pump/VFD automation, and safety cutoff logic.

Application: Treatment of rinse water and spent chemicals

Features: pH sensors, chemical dosing pumps, agitator control, sludge handling, and SCADA integration.

Features: pH sensors, chemical dosing pumps, agitator control, sludge handling, and SCADA integration.

Note:

We do not provide mechanical systems or complete plant turnkey execution. Only electrical & automation scope is handled.

Panels installed for:

01

Zinc & Nickel Electroless Plating

02

ED Coating Plants

03

Industrial Powder Coating Lines

Key Benefits

Modular Panel Architecture

Industrial-grade Reliability

Reduced Downtime

Custom PLC/HMI Logic

Remote Monitoring Options

Energy Optimization Features

Testimonial

Happy Client Says About Us

Dinesh kumar

Rajesh kumar Jha

Vinoth Prakash Krishnamoorthy

kamal ts

Rajasekaran Murugesan

Gopal Haris